USA SALES

CANADA SALES

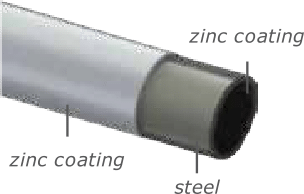

CONDUCTION PIPE

Conduction pipe is produced using the hot-reduction method, which allows the steel to normalize and obtain qualities ideal for the conduction of liquids or gases. The pipe is hot-dip galvanized, which guarantees uniform coating interior and exterior surfaces and provides corrosion resistance superior to that of other processes.

Product available in:

CHARACTERISTICS

- Diameters from 15 to 100 mm (1/2 "to 4") in bare steel, galvanized or varnished pipe

- Diameters from 15 to 150 mm (1/2 "to 6") in bare steel and varnished pipe

- On wall C-40, C-80

- With standard lengths of 6.40 m

- The finishes are smooth, beveled and threaded

- Meets and exceeds standards NMX-B-177 and ASTM-A-53

USES AND APPLICATIONS

- Conduction of liquids and gases

- Residential and industrial construction

- Construction of dams and drainages

- Warehouses, buildings, bridges

- Hospitals and restaurants

TECHNICAL INFORMATION

Dimensions and characteristics NMX-B-177 (ASTM-A-53) | CERTIFICATE CERTIMEX CP-2186-2015 | CP-2187-2015

| DESIGNATION | SCHEDULE | EXTERNAL DIAMETER | THICKNESS | HYDROSTATIC PRESSURE | WEIGHT | BARE WEIGHT | GALVANIZED WEIGHT | BARE WEIGHT | PACKING | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mm | in | mm | in | mm | in | kg / cm² | lb / in² | kg / m | lb / ft | kg x 6.40 m | kg x 6.40 m | kgs x Bundle | pipes x Bundle | |

| 15 | 1/2 | 40 | 21.34 | 0.840 | 2.77 | 0.109 | 49 | 700 | 1.27 | 0.85 | 8.11 | 8.36 | 1030 | 127 |

| 80 | 21.34 | 0.840 | 3.73 | 0.147 | 60 | 850 | 1.62 | 1.09 | 10.37 | 10.68 | 1317 | 127 | ||

| 20 | 3/4 | 40 | 26.67 | 1.050 | 2.87 | 0.113 | 49 | 700 | 1.68 | 1.13 | 10.78 | 11.10 | 1369 | 127 |

| 80 | 26.67 | 1.050 | 3.91 | 0.154 | 60 | 850 | 2.20 | 1.48 | 14.05 | 14.47 | 1784 | 127 | ||

| 25 | 1 | 40 | 33.40 | 1.315 | 3.38 | 0.133 | 49 | 700 | 2.50 | 1.68 | 16.01 | 16.49 | 1457 | 91 |

| 80 | 33.40 | 1.315 | 4.55 | 0.179 | 60 | 850 | 3.24 | 2.17 | 20.7 | 21.33 | 1884 | 91 | ||

| 32 | 1 1/4 | 40 | 42.16 | 1.660 | 3.56 | 0.140 | 70 | 1000 | 3.39 | 2.27 | 21.67 | 22.32 | 1972 | 91 |

| 80 | 42.16 | 1.660 | 4.85 | 0.191 | 105 | 1500 | 4.46 | 3.00 | 28.57 | 29.43 | 1743 | 61 | ||

| 40 | 1 1/2 | 40 | 48.26 | 1.900 | 3.68 | 0.145 | 70 | 1000 | 4.05 | 2.72 | 25.91 | 26.69 | 2358 | 91 |

| 80 | 48.26 | 1.900 | 5.08 | 0.200 | 105 | 1500 | 5.41 | 3.63 | 34.62 | 35.66 | 2112 | 61 | ||

| 50 | 2 | 40 | 60.33 | 2.375 | 3.91 | 0.154 | 162 | 2300 | 5.44 | 3.66 | 34.83 | 35.87 | 2124 | 61 |

| 80 | 60.33 | 2.375 | 5.54 | 0.218 | 176 | 2500 | 7.48 | 5.03 | 47.88 | 49.32 | 1772 | 37 | ||

| 65 | 2 1/2 | 40 | 73.03 | 2.875 | 5.16 | 0.203 | 176 | 2500 | 8.63 | 5.80 | 55.23 | 56.89 | 2044 | 37 |

| 80 | 3 | 40 | 88.90 | 3.500 | 5.49 | 0.216 | 155 | 2200 | 11.29 | 7.58 | 72.23 | 74.39 | 1372 | 19 |

| 100 | 4 | 40 | 114.30 | 4.500 | 6.02 | 0.237 | 134 | 1900 | 16.07 | 10.80 | 102.87 | 105.96 | 1955 | 19 |

| 150 | 6 | 40 | 168.28 | 6.625 | 7.11 | 0.280 | 105 | 1500 | 28.27 | 18.99 | 180.9 | 186.32 | 1809 | 10 |

Note: Tolerances in outer diameter and thickness based on corresponding standards.

Physical and chemical requirements

| REQUIREMENTS | ASTM-A53 | |

| NMX-B-177 | ||

| GRADE A | GRADE B | |

| Minimum tensile strength kg / cm² (lb / in²) | 3375 (48,000) | 4219 (60,000) |

| Minimum Yield Point, kg / cm² (lb / in²) | 2109 (30,000) | 2461 (35,000) |

| % Minimum elongation in 50mm (2") | Calculate | |

| MAXIMUM% | ||

| Carbon | 0.250 | 0.300 |

| Manganese | 0.950 | 1.200 |

| Phosphorus | 0.050 | 0.050 |

| Sulfur | 0.045 | 0.045 |

| Copper | 0.400 | 0.400 |

| Nickel | 0.400 | 0.400 |

| Chrome | 0.400 | 0.400 |

| Molybdenum | 0.150 | 0.150 |

| Vanadium | 0.080 | 0.080 |

Dimensions and characteristics of the pipe for cople ASTM A-865

| DESIGNATION | OUTSIDE DIAMETER | THICKNESS | HYDROSTATIC PRESSURE | WEIGHT | PACKAGING | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mm | in | mm | in | mm | in | kg / cm² | lb / in² | lb / ft | kg x 6.40 m | lb x 21 ft | kgs x bundle | pipes x bundle |

| 15 | 1/2 | 26.67 | 1.05 | 4.37 | 0.172 | 70 | 1000 | 1.61 | 15.38 | 33.9 | 1399 | 91 |

| 20 | 3/4 | 33.4 | 1.315 | 5.21 | 0.205 | 70 | 1000 | 2.43 | 23.17 | 51.08 | 2108 | 91 |

| 25 | 1 | 40.03 | 1.576 | 5.33 | 0.21 | 70 | 1000 | 3.07 | 29.21 | 64.4 | 1782 | 61 |

| 32 | 1 1/4 | 48.26 | 1.9 | 5.46 | 0.215 | 100 | 1420 | 3.87 | 36.89 | 81.33 | 1365 | 37 |

| 40 | 1 1/2 | 55.88 | 2.2 | 6.22 | 0.245 | 100 | 1420 | 5.12 | 48.77 | 107.53 | 1756 | 36 |

| 50 | 2 | 69.85 | 2.75 | 7.11 | 0.28 | 100 | 1420 | 7.39 | 70.42 | 155.26 | 1408 | 20 |

Dimensions and characteristics of the thread in the std pipe and in cople - ANSI B1.20.1

| PIPE | THREADS | COPLES | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DESIGNATION | EXTERNAL DIAMETER | THREADS | EXTREME OF PIPE HAND TIGHT | EFFECTIVE LENGTH | TOTAL LENGTH | DIAMETER OF THE STEP. IN THE PLANE HAND- TIGHTENED | EXTERNAL DIAMETER | LENGTH | NUMBER OF THREADS TIGHTENED BY HAND | ||||||||

| NPS | D | L1 | L2 | L4 | E1 | W | NL | ||||||||||

| mm | in | mm | in | mm | in | mm | in | mm | in | mm | in | mm | in | mm | in | ||

| 15 | 1/2 | 21.34 | 0.840 | 14 | 8.13 | 0.32 | 13.56 | 0.53 | 19.85 | 0.78 | 19.77 | 0.78 | 27.00 | 1.06 | 38 | 1/2 | 5 |

| 20 | 3/4 | 26.67 | 1.050 | 14 | 8.61 | 0.34 | 13.86 | 0.55 | 20.15 | 0.79 | 25.12 | 0.99 | 33.35 | 1.31 | 39 2/3 | 1 9/16 | 5 |

| 25 | 1 | 33.40 | 1.315 | 11 1/2 | 10.16 | 0.40 | 17.34 | 0.68 | 25.01 | 0.99 | 31.46 | 1.24 | 40.03 | 1.58 | 49/5 | 115/16 | 5 |

| 32 | 1 1/4 | 42.16 | 1.660 | 11 1/2 | 10.67 | 0.42 | 17.95 | 0.71 | 25.62 | 1.01 | 40.22 | 1.58 | 48.26 | 1.90 | 50 4/5 | 2 | 5 |

| 40 | 1 1/2 | 48.26 | 1.900 | 11 1/2 | 10.67 | 0.42 | 18.38 | 0.72 | 26.04 | 1.03 | 46.29 | 1.82 | 55.88 | 2.20 | 50 4/5 | 2 | 5 1/2 |

| 50 | 2 | 60.33 | 2.375 | 11 1/2 | 11.07 | 0.44 | 19.22 | 0.76 | 26.88 | 1.06 | 58.33 | 2.30 | 69.85 | 2.75 | 52 2/5 | 2/16 | 5 1/2 |

| 65 | 2 1/2 | 73.03 | 2.875 | 8 | 17.32 | 0.68 | 28.89 | 1.14 | 39.91 | 1.57 | 70.16 | 2.76 | 82.55 | 3.25 | 77 4/5 | 3 V6 | 5 1/2 |

| 80 | 3 | 88.90 | 3.500 | 8 | 19.46 | 0.77 | 30.48 | 1.20 | 41.50 | 1.63 | 86.07 | 3.39 | 101.60 | 4.00 | 79 3/8 | 31/8 | 5 1/2 |

| 100 | 4 | 114.30 | 4.500 | 8 | 21.44 | 0.84 | 33.02 | 1.30 | 44.04 | 1.73 | 11.43 | 4.39 | 127.00 | 5.00 | 87 1/3 | 3 7/16 | 5 |

Coples

| DESIGNACION NPS | EXTERNAL DIAMETER | LENGTHS | NUMBER OF THREADS TIGHTED BY HAND | |||

|---|---|---|---|---|---|---|

| W | NL | |||||

| mm | in | mm | in | |||

| 15 | 1/2 | 27 | 1.063 | 38 | 1 1/2 | 5 |

| 20 | 3/4 | 33 | 1.313 | 48 | 1 9/16 | 5 |

| 25 | 1 | 40 | 1.576 | 49 | 1 15/16 | 5 |

| 32 | 1 1/4 | 48 | 1.300 | 50 | 2 | 5 |

| 40 | 1 1/2 | 56 | 2.200 | 50 | 2 | 5 1/2 |

| 50 | 2 | 70 | 2.750 | 52 | 2 1/16 | 5 1/2 |

Threading Chart

Nomenclature of specifications corresponding to the above tables

BUILD TOGETHER, RISE HIGHER.

The S&P Steel team is ready to bring your ideas to life. Our steel experts operate with deft and efficiency, ensuring impeccable results. Let’s build something extraordinary, and uplift each other in the process.