USA SALES

CANADA SALES

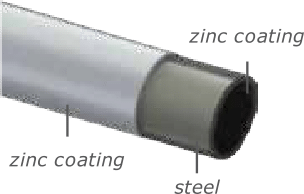

ELECTRICAL RIGID STEEL CONDUIT

Steel pipe with longitudinal welding for conduction of electrical wiring, made of high-quality steel, from which a malleability is obtained that facilitates the bending and threading of the product.

Cold or hot manufacturing process that complies with national standards NMX-J-534-ANCE-2008 and international UL-6; galvanized by the hot dip process, which guarantees a uniform galvanization both inside and outside giving it exceptional corrosion resistance.

The manufacturing processes are monitored by strict quality controls such as Eddy Cur- rents, Precee Test and 90 ° Bending. Certified by Underwriters Laboratories Inc. (UL), ANCE and LAPEM-CFE.

Product available in:

CHARACTERISTICS

- In diameters ranging from 15 to 100 mm (1/2 "to 4")

- In standard lengths of 3.20 and 3.05 m with thread and cap / coupling

- Ideal malleability for bending and threading

- Maximum safety in protection of electrical wiring

- Easy to install and secure due to its rigidity

USES AND APPLICATIONS

- Electrical substations

- Department stores

- Buildings

- Warehouses

- Airports

- Parking lots

TECHNICAL INFORMATION

Dimensions and characteristics NMX-J534 length 3.20 mts (10.4 ft) // ANCE D00036A / 20130829 // ced.40 CFE-LAPEM- K311D-K1537-12

| DESIGNATION | NOMINAL EXTERNAL DIAMETER | THICKNESS | WEIGHT | PACKING | ||||||||

| mm | in | mm | in | mm | in | Kg / m | Lb / ft | Kg x 3.20m | Kg x Bundle | Lb x 10.4 ft | Lb x Bundle | Pipes x Bundle |

| 16 | 1/2 | 21.3 | 0.840 | 2.8 | 0.109 | 1.27 | 0.85 | 4.06 | 515 | 8.86 | 1125 | 127 |

| 21 | 3/4 | 26.7 | 1.050 | 2.9 | 0.113 | 1.68 | 1.13 | 5.39 | 685 | 11.77 | 1495 | 127 |

| 27 | 1 | 33.4 | 1.315 | 3.4 | 0.133 | 2.50 | 1.68 | 8.00 | 728 | 17.48 | 1590 | 91 |

| 35 | 1 1/4 | 42.2 | 1.660 | 3.6 | 0.140 | 3.39 | 2.27 | 10.83 | 986 | 23.66 | 2153 | 91 |

| 41 | 1 1/2 | 48.3 | 1.900 | 3.7 | 0.145 | 4.05 | 2.72 | 12.96 | 1179 | 28.29 | 2575 | 91 |

| 53 | 2 | 60.3 | 2.375 | 3.9 | 0.154 | 5.44 | 3.66 | 17.41 | 1062 | 38.03 | 2320 | 61 |

| 63 | 2 1/2 | 73.0 | 2.875 | 5.2 | 0.203 | 8.63 | 5.80 | 27.61 | 1022 | 60.3 | 2231 | 37 |

| 78 | 3 | 88.9 | 3.500 | 5.5 | 0.216 | 11.29 | 7.58 | 36.11 | 686 | 78.86 | 1498 | 19 |

| 103 | 4 | 114.3 | 4.500 | 6.0 | 0.237 | 16.07 | 10.8 | 51.44 | 977 | 112.32 | 2134 | 19 |

Note: Tolerances in outer diameter and thickness based on the corresponding standard.

Dimensions and characteristics UL-6 length 3.05 mts (10 ft) ced.40 // UL E156557 / LAPEM K311D-12

| DESIGNATION | NOMINAL EXTERNAL DIAMETER | THICKNESS | WEIGHT | WEIGHT PER TUBE | NATIONAL MARKET | EXPORT MARKET | |||||||||

| mm | in | mm | in | mm | in | kg / m | lb / ft | kg x 3.05m | lb x 10 ft | kg x bundle | lb x bundle | Pipes x bundle | kg x bundle | lb x bundle | Pipes x bundle |

| 16 | 1/2 | 21.3 | 0.840 | 2.6 | 0.104 | 1.22 | 0.82 | 3.71 | 8.18 | 472 | 1039 | 127 | 929 | 2046 | 250 |

| 21 | 3/4 | 26.7 | 1.050 | 2.7 | 0.107 | 1.61 | 1.08 | 4.90 | 10.79 | 622 | 1370 | 127 | 979 | 2157 | 200 |

| 27 | 1 | 33.4 | 1.315 | 3.2 | 0.126 | 2.38 | 1.60 | 7.27 | 16.02 | 662 | 1457 | 91 | 872 | 1922 | 120 |

| 35 | 1 1/4 | 42.2 | 1.660 | 3.4 | 0.133 | 3.23 | 2.17 | 9.85 | 21.71 | 897 | 1976 | 91 | 887 | 1954 | 90 |

| 41 | 1 1/2 | 48.3 | 1.900 | 3.5 | 0.138 | 3.87 | 2.60 | 11.80 | 25.99 | 1074 | 2365 | 91 | 944 | 2079 | 80 |

| 53 | 2 | 60.3 | 2.375 | 3.7 | 0.146 | 5.18 | 3.48 | 15.79 | 34.79 | 963 | 2122 | 61 | 947 | 2087 | 60 |

| 63 | 2 1/2 | 73.0 | 2.875 | 4.9 | 0.193 | 8.24 | 5.53 | 25.12 | 55.33 | 929 | 2047 | 37 | 929 | 2047 | 37 |

| 78 | 3 | 88.9 | 3.500 | 5.2 | 0.205 | 10.75 | 7.22 | 32.78 | 72.21 | 623 | 1372 | 19 | 983 | 2166 | 30 |

| 103 | 4 | 114.3 | 4.500 | 5.7 | 0.225 | 15.30 | 10.28 | 46.67 | 102.82 | 887 | 1954 | 19 | 933 | 2056 | 20 |

Note: Tolerances in outer diameter and thickness based on the corresponding standard.

Maximun number of electrical conductors to be used in conduit piping

| CAL / WIRE | in | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 4 |

| MCM AWG | ||||||||||

| 16 | 6 | 10 | 17 | 30 | 41 | 68 | 98 | 150 | - | |

| 14 | 4 | 6 | 10 | 18 | 25 | 41 | 58 | 90 | 155 | |

| 12 | 3 | 5 | 8 | 15 | 21 | 34 | 50 | 76 | 132 | |

| 10 | 1 | 4 | 7 | 13 | 17 | 29 | 41 | 64 | 110 | |

| 8 | 1 | 3 | 4 | 7 | 10 | 17 | 25 | 38 | 67 | |

| 6 | 1 | 1 | 3 | 4 | 6 | 10 | 15 | 23 | 41 | |

| 4 | 1 | 1 | 1 | 3 | 5 | 8 | 12 | 18 | 31 | |

| 3 | - | 1 | 1 | 3 | 4 | 7 | 10 | 16 | 28 | |

| 2 | - | 1 | 1 | 3 | 3 | 6 | 9 | 14 | 24 | |

| 1 | - | 1 | 1 | 1 | 3 | 4 | 7 | 10 | 18 | |

| 0 | - | - | 1 | 1 | 2 | 4 | 6 | 9 | 16 | |

| 0 | - | - | 1 | 1 | 1 | 3 | 5 | 8 | 14 | |

| 0 | - | - | 1 | 1 | 1 | 3 | 4 | 7 | 12 | |

| 0 | - | - | - | 1 | 1 | 2 | 3 | 6 | 10 | |

| 250 | - | - | - | 1 | 1 | 1 | 3 | 5 | 8 | |

| 300 | - | - | - | 1 | 1 | 1 | 3 | 4 | 7 | |

| 350 | - | - | - | 1 | 1 | 1 | 1 | 3 | 6 | |

| 400 | - | - | - | - | 1 | 1 | 1 | 3 | 6 | |

| 500 | - | - | - | - | 1 | 1 | 1 | 3 | 5 | |

| 699 | - | - | - | - | - | 1 | 1 | 1 | 4 | |

| 700 | - | - | - | - | - | 1 | 1 | 1 | 3 | |

| 750 | - | - | - | - | - | 1 | 1 | 1 | 3 | |

| 800 | - | - | - | - | - | 1 | 1 | 1 | 3 | |

| 900 | - | - | - | - | - | 1 | 1 | 1 | 3 | |

| 1000 | - | - | - | - | - | 1 | 1 | 1 | 3 | |

| 1250 | - | - | - | - | - | - | 1 | 1 | 1 | |

| 1500 | - | - | - | - | - | - | - | 1 | 1 | |

| 1750 | - | - | - | - | - | - | - | 1 | 1 | |

BUILD TOGETHER, RISE HIGHER.

The S&P Steel team is ready to bring your ideas to life. Our steel experts operate with deft and efficiency, ensuring impeccable results. Let’s build something extraordinary, and uplift each other in the process.